Tailor-Made Solution

Tailor-Made Solution

-

From ID design, scheme development, software application, to production and delivery to customers, every step is strictly controlled to ensure that each product is of high quality.

-

From ID design, scheme development, software application, to production and delivery to customers, every step is strictly controlled to ensure that each product is of high quality.

-

From ID design, scheme development, software application, to production and delivery to customers, every step is strictly controlled to ensure that each product is of high quality.

-

From ID design, scheme development, software application, to production and delivery to customers, every step is strictly controlled to ensure that each product is of high quality.

Products

Products

-

Rugged Touch Mobile ComputerHigh-performance large-capacity storage system...Read More

-

Rugged Tablet PCHigh performance storage solutions for enterprises, designed for high reliability...Read More

-

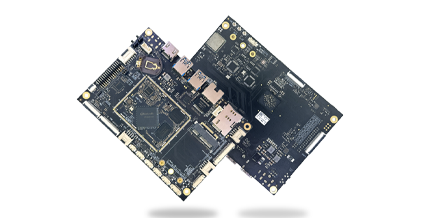

Multifunctiona Control HostHigh performance storage solutions for enterprises, designed for high reliability...Read More

-

Vehicle-Mounted TabletHigh performance storage solutions for enterprises, designed for high reliability....Read More

-

Medical Handheld EndoscopeHigh performance storage solutions for enterprises, designed for high reliability...Read More

-

S73 rugged tablet pc1-6High performance storage solutions for enterprises, designed for high reliability...Read More

Applications

Applications

-

The logistics and warehousing industry requires a focus on durable and portable handheld PDAs and ruggedized tablet computers, equipped with efficient data processing, customizable features such as barcode scanning, RFID, and long-lasting battery life.

-

Lanodo Technology focuses on the field of smart healthcare, providing customized communication and intelligent medical device solutions.

-

Smart Forestry uses advanced technology and digital tools to manage and monitor forest resources, including the use of drones and satellite imagery for forest resource surveys...

-

The oil and gas industry involves exploration, production, processing, and sales, and is crucial for global energy supply...

-

Discover the best rugged tablets for the construction industry designed to boost site productivity and durability...

-

Customized handheld PDAs and rugged tablets are used for on-site data collection and fault diagnosis in the field of electric power engineering。。。

-

The financial and banking industry provides services such as fund management, investment, loans, and currency transactions...

-

Intelligent Transportation System (ITS) uses advanced technology to improve transportation efficiency and safety...

News

-

The company will regularly update the latest company news, industry information, media coverage, and technical articles to provide you with comprehensive information services.

-

The latest information and developments, including market trends, policies and regulations, competitor movements, new technological applications, and other related content.

-

Media reports typically introduce new products, technologies, or industry trends, and modern information technology products such as handheld PDAs and industrial tablets may also receive attention in media coverage.

-

Technical articles typically delve into the technical details, design principles, performance characteristics, and application scenarios of specific technological products.

Service & Support

Service & Support

-

The video center will showcase product features, usage methods, and technical details to provide users with a more intuitive understanding and operational guidance.

-

Here you may find the answers you need. If you still have questions, we are here to serve you wholeheartedly.

-

Wholehearted and sincere service, with professional customer service available 24/7, providing you with comprehensive service and professional after-sales support.

-

You can find the product manuals, maintenance manuals, and product software versions for all kinds of products here, and you can download them by yourself.

About Us

About Us

-

The company's strength lies in its strong research and development capabilities, customised solutions, innovative technological applications, and rapid response to market demands.

-

The company's strength lies in its strong research and development capabilities, customised solutions, innovative technological applications, and rapid response to market

-

The company's strength lies in its strong research and development capabilities, customised solutions, innovative technological applications, and rapid response to market

-

The company's strength lies in its strong research and development capabilities, customised solutions, innovative technological applications, and rapid response to market